11 ShongLin Xi Road,, Xin'An, Chang'An Town, Dongguan Guangdong Province, China

- chuang Xiang Jing Mi

- Quality

Quality

Quality

At CX MOLD, quality is the cornerstone of our operations. We implement an Integrated Quality Management System (QMS) aligned with industry-leading standards, reinforced by our proprietary Three-Stage Inspection Protocol to ensure excellence at every phase of mold manufacturing.

Preventive Quality Measures

Design Validation: Advanced simulation software and rich experience verifies mold structural integrity and functionality prior to production.

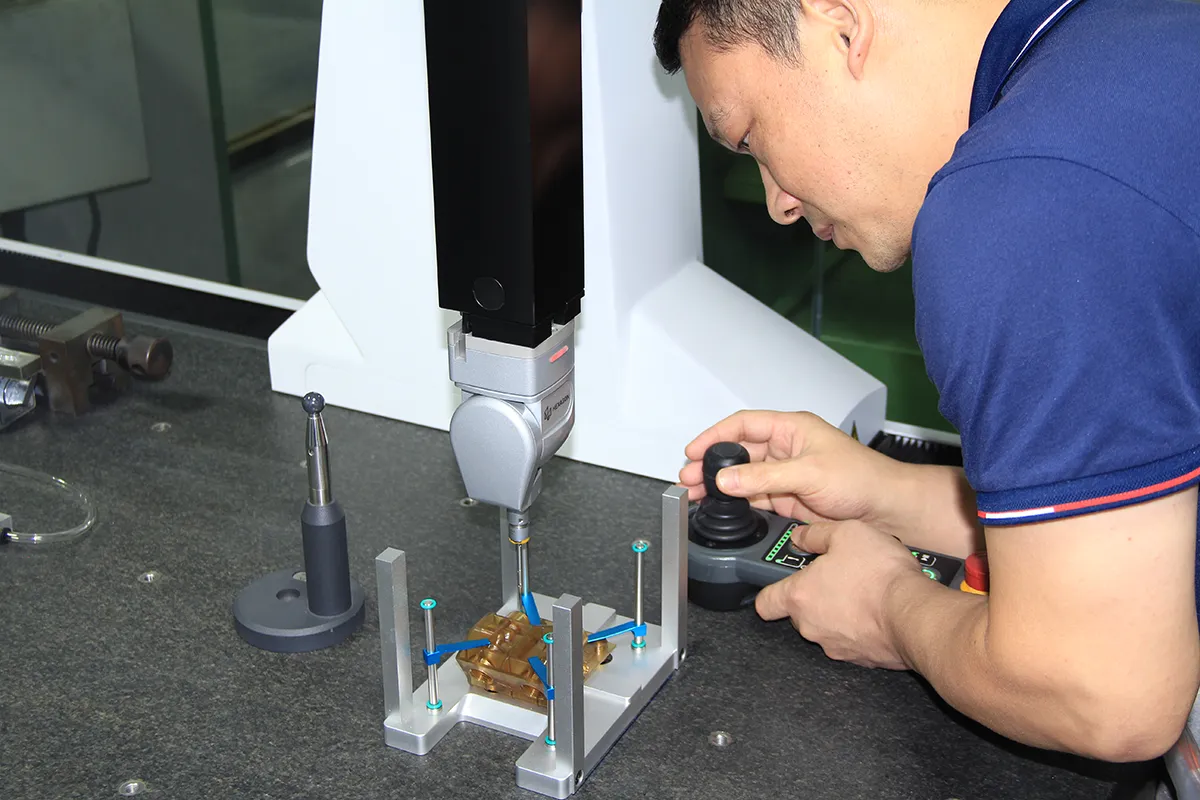

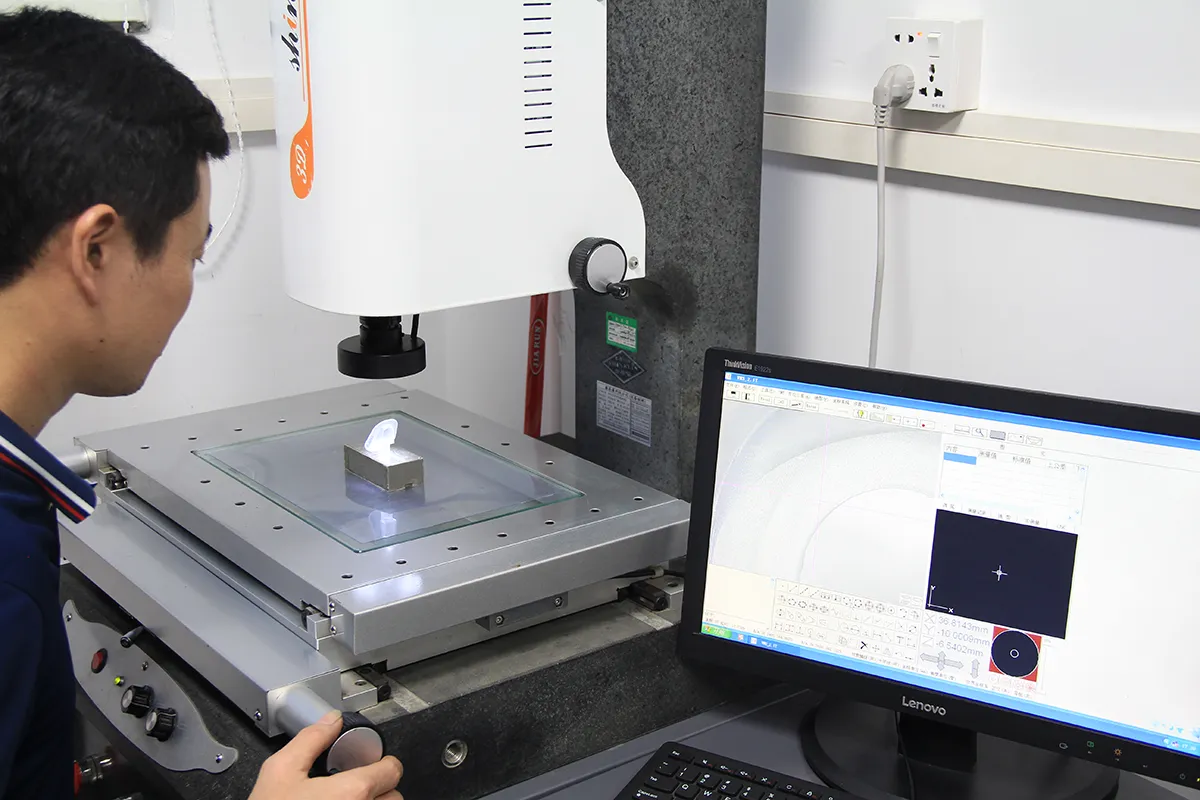

Material Certification: All steels and copper electrodes undergo certified CMM inspection with full traceability reports.

In-Process Monitoring

Statistical Process Control (SPC): Real-time CPK analysis ensures machining stability and dimensional consistency.

Multi-Department Cross-Checks: Critical parameters are validated by engineering, production, and QA teams at defined checkpoints.

Final Validation & Documentation

FAI,CPK & PPAP Compliance: First Article Inspection and full PPAP documentation provided for customer approval.

Mold Qualification Testing: Production trials with detailed validation reports on cycle time, part dimensions, and durability metrics.

Chuangxiang Precision Mould Addr.

11 ShongLin Xi Road,, Xin’An, Chang’An Town, Dongguan Guangdong Province, China

HuiZhou Company:

West Floor 2, Building 6, Yifu Wan II Industrial Park, Longxi Town, Boluo County, Huizhou City, Guangdong Province, China

Contact

-

-

Contact: MR Frankie Yu

-

Mobile :+86 186 8229 1881

-

Tel :+86 0769 82283716

© All Copyright by Chuang Xiang Precision Power by Pedoli